|

| Gemlab's Model M76-1700 ("MAXXI MUFFLE") vertical muffle furnace is the top of line with unparallel technology combined with superior longevity and incredible versatility designed by Ted Themelis for flawless performance. The furnace is composed of four integrated modules: Power module, Furnace module,, temperature control module, atmosphere control module. The furnace is able for heat-treating between 2,200 to 2,500 carats of rubies-sapphires in air, reducing, oxidizing or in vacuum, with or without additives at temperature from 1200oC to 1700oC (1200oC to 1800oC for model M76-1800). The furnace may be used with/without muffle to increase loading capacity. |

|

- Semi-floor model 400 (D) x 400 (W) x 1100 (H) mm

- Net weighs is 108 kgs

- Oper. temp.1200oC to 17000C (air); 1200oC to 1500oC (vacuum using full muffle)

- Loading capacity: About 3,380 carats of ruby-sapphire using a muffle, or about 3,800 carats without muffle

- Double steel shell design with dual air cooling fans

- Full atmosphere control for reducing-oxidizing

- Vacuum pump with valve and vacuum gauge

- Molybdenum desilicide 1800-grade elements

- Single program, auto tune, 51-step, artificial intelligent temperature programmer/controller

- SCR (Silicon Control Rectifier) and Trigger controller

- Long life Pt/Rh “B” type thermocouples (2 sets)

- High energy fiber-board 1900-grade lining throughout

|

- Analog and digital voltmeter, ammeter, on-off switch, key-switch, alarm-buzzer

- Electric elevator control (UP, DOWN) for slow/rapid loading-unloading

- Power: 2.2 KVA, 220 Vac 20 A outlet (1 phase)

- Economical power consumption, only 1900 watts needed to maintain operating temp. at 1700oC

- Up gradable for 1800oC operation

- Safe and easy operation

- Long-lasting performance

- Delivery 6-8 weeks after deposit, FOB Bangkok

- One year warranty on all electric, electronic parts

|

|

- Power isolated transformer

- Elevator assembly with controls (Up, Down)

- Incoming power voltmeter and ammeter shown the power consumption

- Mains (208-230 VAC, 20A, 1 phase) and breaker circuit

|

- 1900-grade fiberboard insulation

- Molybdenum disilicide 1800-grade heating elements

- Port for muffle and elevator assemblies

- Heating chamber octagon-shape

|

- Artificial intelligent single program main temperature programmer-controller with 51-segments and accuracy +/- 1oC plus 1 digit.

- Artificial intelligent temperature limit controller accuracy +/- 1oC with single set al ram point shuts down the furnace in the event the main programmer temperature controller is failed

- B-type thermocouple (2 sets)

- SCR (Silicon Control Rectifier), controller and Trigger for power control management

- Instrumentation: Hour meter shown heating element consumption hours, start, stop emergency buttons, on-off switch, IN analog ammeter, voltmeter, OUT analog voltmeter, ammeter.

|

- Dual One-way gas valves

- Dual Pressure gas regulators

- Dual Pressure gauges

- Dual Gas mixer

- Dual on-off valves

- Dual 150 mm flow meters

- Back pressure gauge

- Hoses, brass inlet, exhaust port

|

|

|

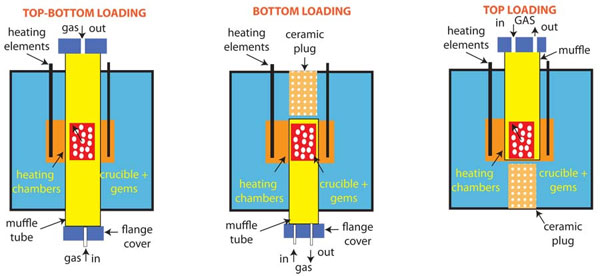

Model M76 uses full muffle tube, OBE (Open-Both-Ends), OD= 76 mm, L=610 mm or optimum performance where precise control of the atmosphere conditions or vacuum is required. The crucible may be loaded in the chambers from the top, or bottom using the electric elevator. |

Most heating processes can be performed using the half-muffle tube, COE (Close-One-End), OD= 76 mm, L=280 m in either top or bottom loading-unloading configurations. In this mode, may also be used where atmosphere conditions with positive pressure, or vacuum are needed. The crucible is loaded in the chambers from the top or bottom using the electric elevator. |

By removing the muffle tube and inserting special ceramic plugs, the furnace is converted to a bottom or top-loaded furnace allowing to increase the load of the gemstones by 30% to be heated. |

|

|

| |

|